Alan Coker (left) and Matt Francklow, Creation Reprographics

The formation of dots during processing is vital to the end result, and the key word is control. Platemaking technology continues to evolve driven by market requirements of faster speeds, more environmentally sound solutions, higher print quality and lower costs. By Neel Madsen.

Processing plates using water has gained a dedicated following in recent years as demands for more sustainable working practices from brands have increased.

Creation Reprographics, in Daventry in the UK, has been using the AWP wasterwash plate system from Asahi Photoproducts for the past three years.

Owner Matt Francklow said, ‘Sustainability is truly coming to the fore in print. With this high quality waterwash plate, it’s the final check for retailers. At Creation, we have positioned ourselves in the premium segment of the market, competing head on with gravure in Europe and serving those customers that demand the best in the UK. Our AWP results are simply unrivalled – consistency, slightly raised ink density and better lay down, good minimum dot, and speed to press are all achieved – making the printer’s job easy. The system works across all substrates, and we see a real demand for this level of performance in premium flexible packaging applications.’

The company prides itself on its approach to environmental sustainability. It is investing in energy management solutions across sites and looking at whether it can recycle rainwater to do the washing of the plates.

Alan Coker, business development manager, commented, ‘Reducing waste in the platemaking game is critical to your profitability. Throwing polymer in the bin is just not acceptable. Asahi’s supports our AWP plate technology investment with preventative maintenance and machine audit visits.

‘Our customers are delighted as well. Since the plates do not suffer from distortion due to solvent swelling or increased temperature, we are achieving better registration and consistency on press. With the start-up time absolutely minimised, we’re making plates in less than 90 minutes. Combine that with suitability for four colour process set applications, and you have an extremely compelling value proposition.’

The Asahi AWP technology has been designed from the outset as an environmental plate solution. The water used in the plate processing is filtered after use and recycled. The unexposed polymer residues are collected as ‘dry cake’ and repurposed as a combustive agent for incineration waste plants.

Dual washing

Another environmentally friendly system is the DigiWash range from Dantex. This has been developed as an extended form of the established AQF7900 Combination Unit. It features dual-action washing and an automatic brush height adjustment option for different plate thicknesses.

The DigiWash processor from Dantex

After main exposure, the plate is placed on a tacky plate holder that transports it into the processor. The plate carriage moves both backwards and forwards through the wash section, initially at the same time as the orbital brush action to ensure a quicker wash. At the end of the pre-determined cycle, the plate is moved to the unload position where a rotary brush removes any remaining debris and a sponge roller eliminates any surface water. On completion, the lid can be opened and the plate move to the multi-function cabinet located under the wash tank area. This combines dryers with post-exposure and detack to offer savings in time. During this phase of the process, washout can be started for another plate.

The combination processor is available in three models – the DW 2735 for 700 x 900 mm plates, the DW 4835 for 900 x 1200 mm plates and the DW 4260 for plates up to 1067 x 1524 mm. It has a tank capcity of 90 litres and can be combined with Dantex’s Aquaclean filtration system for the recycling of the water used in the process.

Far east application

Flint Group’s nyloflex NExT exposure technology creates flat top dots and can be incorporated into any digital platemaking workflow regardless of plate format and thickness.

Kyoung Wha, a family business in the south Korean city of Ansan offers a comprehensive service package to its clients. This ranges from design to finished plates, with the major focus on the corrugated market.

The company has recently installed a nyloflex NExT Exposure FV system. The exposure technology utilises a high intensity UV-A LED light source to conduct rapid crosslinking of the photopolymer surface. The high UV-A output results in a virtual 1:1 image reproduction from the digital file to the finished plate. In flexible packaging, printing plates exposed with this technology allow excellent ink transfer, particularly in solids, and in corrugated printing, fluting will considerably be reduced.

To take full advantage of the technology, Kyoung Wha uses nyloflex NEF printing plates, which have been especially developed for this exposure system. Director Jihoon Chung said, ‘The plate formulation, which is tailor-made for LED exposure, enables a significantly faster processing of the printing plates. We realise a higher quality by the excellent reproduction of the finest details in the highlights. Besides that, our customers benefit from the outstanding printing stability of the plates – less cleaning stops are necessary, with the result of increased efficiency.’

Meanwhile, in Russia

DuPont’s Cyrel DigiFlow is a digital workflow enhancement, which adds a chamber that allows the creation of a controlled atmosphere during the main exposure, for one-to-one reproduction of image elements on the plate, critical to optimising the effects of solid screening patterns.

Danaflex-Nano is a large flexible packaging manufacturer located in Kazan, Russia, which specialises in multilayer barrier films for packaging, including film with nano-layers of aluminum oxide. In 2011, the company decided to bring platemaking in house and installed a DuPont Cyrel system. Shortly after, a Cyrel DigiFlow system was added to further expand capabilities but keeping impact on the environment low.

‘With this new technology, we can demonstrate to our customers that a new level of digital platemaking quality can now be attained. The new DigiFlow 1000 ECLF allows us to produce flat top dots on demand, utilising the resolution of our CDI and the new screening technology to achieve enhanced ink transfer and excellent solid ink density,’ said general manager, Galiullin Aidar Sharipovich. ‘

Production manager Kudosov Andrey Alexadrovich, added, ‘We now have the option to utilise exact 1:1 image reproduction which is necessary to optimise solid screening programs for enhanced solid ink transfer. With this technology no additional plate making steps are required. It was also important for us to offer this new technology without adding production cost. As a result of selecting the Digiflow system, we obtained higher quality packaging for the same cost.’

Surface texture

Kodak’s Flexcel NX system relies on imaging a high resolution mask material, the Thermal Imaging Layer (TIL), which is imaged and then laminated to a photopolymer plate before UV exposure.

At the heart of the system is the Squarespot Imaging Technology, which Kodak originally developed for imaging litho plates. The technology is a way of channelling the edges of a laser beam for a precise, defined dot. The laser is capable of producing 10,000 dpi resolution, which has been divided by four in order to concentrate on creating sharp edges around the dot.

Added to this is the Digicap NX screening option for improved ink transfer from the surface of the plate, resulting in clean, bright colours. A filter applied in the software to the 1-bit tiff file alters the texture of the surface of the plate in order to lay the ink down in a more uniform way, especially in the solid areas. Without using more ink, this offers gravure-like quality with roughly a 10% wider colour gamut.

For sleeves, the Flexcel Direct System offers a complete solution that includes imaging, media and software, optimised to work together in a simple, two-step process that boosts operational efficiency and print quality. The imager utilises Kodak’s high resolution multi-channel laser diode array technology to directly engrave elastomer continuous sleeves to a maximum width of 1600 mm and maximum repeat of 1067 mm.

Imaging

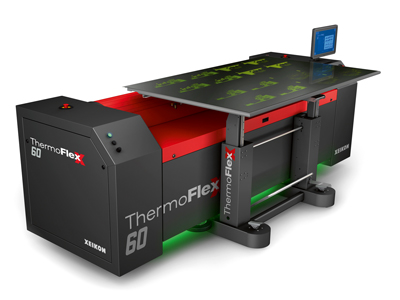

ThermoFlexX has recently introduced a redesigned version of its ThermoFlexX 60 digital flexo plate imager, which offers the same advantages as the larger ThermoFlexX 80. All of the technology incorporated into the larger system is available on the new ThermoFlexX 60.

ThermoFlexX 60 digital flexo plate imager

‘In addition to advancements in technology, we have established a growing network of global dealers and distributors while our customer base has expanded considerably,’ commented Christophe Lievens, director sales and marketing for basysPrint and ThermoFlexX. ‘The ThermoFlexX 80 is the largest imager in our range, and it has attracted significant interest. Models are now in full production at AtoutFlex, a leading service bureau in north-east France, and at a new 800 square metre factory in Bejaia, Algeria, completed recently by the Miller Graphics Group. A third ThermoFlexX 80 has been installed in Egypt and we expect to announce further orders in the near future.’

All ThermoFlexX imagers utilise IPG fibre lasers operating at 1064 nm, which combine low energy consumption with high reliability. The imagers will expose any plate with a LAM layer such as flexo, letterpress and dry offset, as well as Gallus Screeny (digital screen) and ablative film, and they can handle any thickness from a 0.18 mm ablative film to a 6.35 mm flexo plate, and support all relevant technologies, such as flat top dots. This means that if a printer uses plates from any leading supplier, eg Flint, DuPont, Asahi, MacDermid, Toyobo, Toray, they can continue without changing their normal working practices.