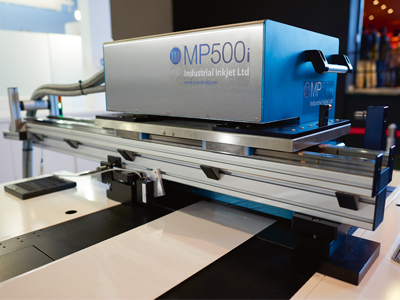

IIJ has developed the MP500i – a 600 dpi monochrome inkjet module

The use of variable data is becoming increasingly common from short run promotions to track and trace labels. By Nessan Cleary.

Conventional flexo presses are extremely effective at producing long runs of identical packs or labels. But there are times when we need to print variable data and there are a number of different digital technologies that we can turn to, depending on the type of data to be printed and the substrates or products to be printed to. This could range from straight forward Print and Apply labels meant for transit packaging through to barcodes printed direct to products or sophisticated labels designed to add value through personalisation.

Philip Easton, managing director of Domino, said that there is an increasing trend in the market towards more variable data, saying, ‘I think that customers are buying it for short run and then they explore the personalisation opportunity it gives. So we are seeing a significant trend towards more variable data.’

Domino has several versions of its N610i inkjet system, including the recently launched hybrid that is designed to be added to an existing flexo set up. It is also available as a standalone digital press and as an inkjet module that can be added to other equipment. Mr Easton said, ‘You can start with a roll to roll and change it to one of the others. It’s completely modular so you can add flexo stations with embossing, laminating or whatever’.

The company sells several inline inkjet modules, such as the K600i, which can be integrated to existing systems. This can run at speeds up to 150 m/min and is typically used for applications such as barcodes and QR codes as well as personalised data and graphics.

At the recent Labelexpo show Domino demonstrated an interesting collaboration with two of its inkjet heads on a GraphiMecc foiling machine. The first head printed black ink, while the second jetted adhesive, which combined with the foiling for a really effective variable data security solution that would be very hard to counterfeit. The obvious application for this is for pharmaceutical use but it is also suitable for security labels for things such as automotive parts.

Xaar has developed a new Print Bar system that can be integrated to existing machinery. Essentially, Xaar has stitched a number of its 1002 printheads together to form a single unit, available in widths from 70 to 560 mm. The 1002 heads are widely used in digital label presses, with several variations so that developers can choose to prioritise image quality or productivity. The unit includes ink channels, electronics to drive the heads and even a workflow so that it can be easily added to a conventional press. At Labelexpo it was shown on Edale/FFEI’s Graphium, a seven colour hybrid press, with the additional printbar module used to add white ink to create an eight colour printer, but it could just as easily be bolted onto a conventional flexo press or even a finishing line.

Mark Alexander, director of business development for Xaar, said, ‘We think that people will use the Print Bar to do variable data on packaging where the whole thing could be printed variable because it’s different languages or you might use it to change the messaging or have different promotions.’

Xaar’s new Print Bar features heads stitched together to print across a 560 mm web

Coding and marking

Mr Alexander also makes a distinction between a full variable data solution, which typically covers the whole width of the press, rather than more basic information. He explained, ‘Coding and marking is typically just doing a barcode or data swatch of very specific data like product codes and date stamps which is quite different from being able to print full variable data text.’

Typically coding and marking is just one colour, usually black, but Mr Alexander argued that some companies are looking to go beyond this. He said, ‘If it’s going to enhance the shelf appeal of packaging it may be that you use multiple colours so you can put some logos and graphics on a case that makes it more useful to the supply chain. So you could pull the front off a corrugated box and have the rest of the packaging as shelf ready.’

Xaar is also in the process of updating its coding and marking offerings, which have been the 128, 126 and 500 series printheads. Mr Alexander noted, ‘We have the 501 with TF technology and we are looking at how we bring that type of product in the coding and marking space.’ The TF technology allows the inks to recirculate in the head, reducing the risk of clogging the heads. He added, ‘Customers always want higher speed. There is a requirement for higher quality bar codes to make them more reliable and readable. People want to start adding colour and to start looking at shelf ready systems.’

Mr Alexander said that another factor is changing demand for inks, noting, ‘We also have people moving from solvent to UV, which is good for fast drying and UV ink sticks to a lot of different things like plastics. Also people are looking for more environmentally friendly solutions.’

However, John Corrall, managing director of Industrial Inkjet is more sceptical about the need for variable demand. He said, ‘There is an idea that the goal of a mono system on a flexo press, where the colours are printed with flexo, is to just print the variables like language information. But when I actually visit customers I find that they are only printing a barcode or a serial number and it’s not really a label but just a tag.’ But he does agree that there is a demand for higher resolution, saying, ‘One of our biggest issues at the moment is with a tiny little barcode which you can print at 360 dpi but we found that we were getting much better results at 600 dpi.’

Industrial Inkjet (IIJ), which uses Konica Minolta printheads, has developed a number of printhead modules that can be added to existing systems. The most recent of these is the MP500, which is a complete single colour printing system that can be added to existing presses or even to finishing kit. It can print full variable images in black or white as well as varnish or spot colours, as well as security inks such as IR black or UV fluorescent. It boasts 600 dpi resolution and can run at up to 50 m/min. It is 520 mm wide so suitable for small packaging systems as well as labels.

Batch numbering

Another possible use of variable data is for track and trace, which mainly applies to the pharmaceutical industry. Mr Corrall noted, ‘I’ve had a lot of discussions with customers for track and trace, but it’s mainly to keep an eye on their distribution chain to prevent splitting of multi packs or to prevent distributors shipping products across borders where prices are different.’

Matt Browne, marketing manager for Videojet, said that track and trace is a growing area, with a lot of regulation coming. But he said that it is less of a concern for industry sectors beyond pharmaceutical. He pointed out that other sectors, such as food, are more interested in batch numbers so that they can trace products quickly if there are problems.

Several vendors are exploring ways to printing directly to products to take steps out of the supply chain, such as the need to print a separate label. Videojet is already active in this area, mainly printing barcodes and batch numbers to primary packs such as bottles and cans. There is a basic choice between continuous inkjet, where a stream of ink is jetted at the product but some is deflected to form drops, and laser engraving. This is suitable for a wide range of applications and substrates and has a lower running cost than inkjet since there are no consumables, but a higher initial capital cost.

Conclusion

There is clearly a growing demand for variable data in some areas, but it very much depends on the application and the market sector. The sheer number of hybrid presses shown at the recent Labelexpo suggest that there is considerable appetite in mixing full colour variable data across the web width, at least for labelling and some flexible packaging. This is mostly to enable short run production, such as for more targeted promotional messages.

There is an established market for coding and marking, both to labels and packaging as well as direct to product, and here the main trend seems to be for higher resolution and greater reliability. Other trends, for greater track and trace or for adding marketing messages to coding and marking tags, seem to be limited to particular market sectors. However, a number of vendors are also working to develop inkjet systems capable of delivering much better graphics capabilities direct to products, mainly bottles and cans, which may in the future create a greater demand for variable data.