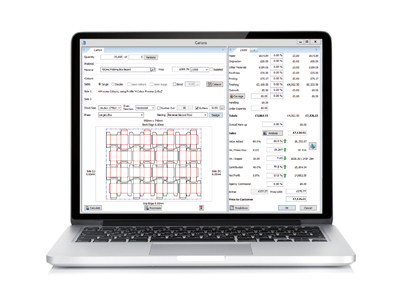

The Tharstern MIS can take account of nested impositions for estimating for packaging

Management information systems are increasingly becoming part of the production workflow. Nessan Cleary explains that integration is the name of the game and that the method of delivery is changing.

We have seen in recent years that flexo presses have become more efficient and more highly automated as manufacturers have designed these machines to minimise both waste and job changeover times. But there is an even simpler way to achieve both of those goals by maximising the production workflow. This in turn means integrating the different applications that make up a modern workflow so that they genuinely work together.

The obvious place to start is with the management information system, or MIS, since it can control everything from the costings for each job through to stock inventory and final invoicing. The MIS should be used to continuously take the pulse of the business, warning if machines are under-utilised or break down too often, indicating if profit margins are being met and flagging up problems such as quotes for a particular type of job failing to be converted to actual jobs.

Check the pulse

To work efficiently, the MIS needs to understand all the issues associated with packaging. Naturally, different vendors take their own approach. Optimus, for example, has announced a new Dash for Packaging option for its Dash MIS due to be launched at drupa. Dash relies on users creating their own rules to tailor the system around their needs. This allows it to produce fairly accurate quotes, with no limitation in terms of substrate, size or quantity.

For the packaging option, Optimus has added a Diecut Knife Database which contains details of a wide range of die knives such as size, shapes on the knife as well as different types of cartonboard and what the final products will look like. The information is added to quotes to produce a more accurate estimate.

Most vendors agree that estimating remains the heart of an MIS. Lee Ward, sales director for Tharstern, said that the ability to estimate for different conditions dictates if that MIS can support multiple print processes such as wide format or packaging. Ward continues, ‘The key thing for estimating packaging is nesting impositions rather than standard imposition for both. With a more commercial print product there are standard shaped products whereas packaging will have irregular shapes so it’s key for an estimating system to understand how that shaped package can be nested on a sheet.’

Tharstern gets around this by integrating with CAD systems that can help with these calculations, such as AG CAD’s Kasemake or Esko’s Artios. Mr Ward explained, ‘Esko Artios has an API so their product is embedded in ours. So you can almost design your drawing within the estimator. You can decide how big the glue flaps are going to be, for example, and can design your box shape within the estimator. That is a pretty rich integration.’

Tharstern, as with any MIS, is continuously updated as new features are added, usually as a direct result of a bespoke implementation for one client then being integrated into the system as a whole. Recent improvements include the ability to mix different shapes together.

Sweet suites

EFI has also relied on integration with CAD programs, particularly Esko’s Automation Engine and Artios, to deal with the layout and nesting issues common in label and packaging workflows. Nick Benkovich, director of portfolio product management, also notes that CIP4 (The International Cooperation for the Integration of Processes in Prepress, Press, and Postpress Organization) has spent a lot of time recently developing suitable packaging imposition standards. He said the company is a big supporter of JDF, adding, ‘In the CIP4 world, we have more certifications than other companies and that’s good for the confidence of our customers.’

The company has gone a step further than the MIS with the creation of a number of Productivity Suites, which are based around its MIS offerings. This includes the Packaging Productivity Suite, which has EFI’s Radius MIS at its core. Each of these suites include a selection of EFI’s many workflow and MIS tools, such as PrintFlow for scheduling and AutoCount for picking up shop floor data as well as the Digital StoreFront web to print system. But whereas in the past these were all developed and sold as separate systems, now EFI has pledged to maintain them as a single, unified suite of products. This guarantees a strong level of integration between the different elements, with no waiting around for one to catch up on developments in another.

Earlier this year EFI announced a number of new features including Workbench, a dashboard that can be set up for different users within a company so that everyone sees the information for their particular role. There is also a new e-commerce module that adds support for Worldpay and is due to be added to the Packaging Suite later this year. EFI has also released a new JobFlow digital print workflow automation program. This supports multi-job submission, extended third-party job processing, workflow sharing and enhanced usability.

In addition, EFI announced a new Corrugated Production suite, mainly based around the workflow technology that EFI acquired last year with Corrugated Technologies Inc. It will cover carton as well as corrugated packaging, mainly with conventional printing though EFI does expect to roll out a Fiery front end for digital printing in this sector.

Making links

Label Traxx has designed and built its MIS specifically for the label and packaging industry. It will be launching version 8 of its MIS software this spring. The release introduces two new modules, a host of other new features and closer integration with Xeikon presses.

‘In today’s data-driven world, the most successful label companies will have instant access to accurate information in a format that is meaningful – and they may need to share that data with other software systems,’ explained commercial manager Jenny Whittle. ‘The new Label Traxx modules have been developed to address the key demands of our customers and this industry. We are arming our customers to face the challenges of managing a modern business.’

Version 8 features include a new API module enabling the sharing of data with many other systems that support HTTP and SOAP protocols. It can be used to link with CRM systems or shipping manifest and labelling software.

Also new is the Financial Centre module for managing financial accounting within a multi-plant business. As mergers and acquisitions continue to trend in the packaging industry, this new module allows remote locations to send their financial data securely to a central or main location for reporting. New consolidated reporting features allow the viewing of data by location or combined as a single entity.

Finally Label Traxx is introducing new two-way communication with the Xeikon press. Previously the MIS would send job data and artwork files directly to the press. Now, once the job is finished, toner usage is sent back to the system.

End to end

Cerm has addressed the web to print side of its business, updating its Web4Labels application to make it easier to use with mobile devices. This system uses flexible information grids so that label printers will be able to customise the information for every individual customer. The idea is that this will make it easier for customers to work within the printers’ workflow via their website.

Cerm’s Web4 Labels application has been optimised for mobile devices

The company has worked with a number of other vendors to integrate its MIS with their systems. This includes Esko, with more than 50 customers connected via the Cerm MIS, as well as Chili Publisher for uploading product artwork, and GSE ink dispensing systems for calculating the right amount of ink.

However, Cerm’s main integration is with Heidelberg, which has owned the company since 2011. The Cerm MIS forms the basis of Heidelberg’s Prinect Business Manager, a fully integrated module within the wider Prinect workflow.

Software platform

As we have seen, just about everybody that is developing anything vaguely related to a packaging workflow starts off with some form of integration with one of Esko’s offerings. Esko itself is improving the integration between its various applications, having announced a new Software Platform. The company has a fairly diverse portfolio, which has mainly come about through acquiring other companies, but there is a lot of synergies across these applications so it makes sense to join them together to leverage their strengths.

Esko has also updated all of its software with broad performance enhancements. Amongst the improvements are new tools and libraries for multi-part POP design in ArtiosCAD 16 and a new set of automated quality assurance tools in Automation Engine. Esko will also integrate its MediaBeacon DAM system with WebCenter to make it easier to share digital assets across a packaging workflow.

But the major feature of the Software Platform lies in the way it is delivered, with many applications offered as SaaS (Software As A Service) and a growing number of modules sold on a subscription basis. This includes a new web-based approval tool in WebCenter called Esko Share and Approve Service. The company will also offer its WebCenter, MediaBeacon, ArtiosCAD Enterprise and Online Editing with Chili Publish options on an SaaS basis.

The great advantage of this approach is that there is less need for companies to invest in and manage their own IT hardware, and it is easier to scale up during busy periods by simply licensing more processing power when needed.

Indeed, there is a growing trend towards greater integration with cloud computing right across the board with many companies planning to launch similar solutions at drupa.

In conclusion, workflow is increasingly about the way that the different applications fit together, rather than the capabilities of any one piece of software. But the way that software is bought is also changing, with more companies switching to a licensed model that includes service and support. It is this support, as well as integration with other systems, that is becoming more important than developing new versions with additional features.