RotoMetrics staggered die with alignment marks

Competition on the supermarket shelves is getting steeper and steeper, so brands are looking at different shapes in labels and packaging to help their products jump out at the customer. Michal Lodej looks at how this, combined with developments in materials, is putting extra demands on flexo printers today.

Holfeld Tool & Die Ltd has seen an increasing demand for bespoke tooling in the label market as brands strive to differentiate their products on the shelves. The company points to the spirits sector in particular as one that is increasingly asking for more intricate designs. For this type of application, the company offers flexible dies which are CNC machine finished to within a +/- 2 microns tolerance.

Security labelling and specialist materials can all be catered for with the company’s options for flexible dies including non-stick and HTD coating. The latter process produces an extremely hard die with exceptional cutting life of up to 400% improvement compared to nickel plating.

The standard die height used in the label industry is a 0.48 mm plate, but there is a growing niche of customers taking the alternative thicker dies. These are used on magnetic cylinders with a 0.78 mm air gap and allow for materials up to 600 microns to be cut compared to 300 microns on a standard die.

Dies for these cylinders often incorporate creasing or scoring blades for the production of promotional items such as boxes. As with 0.48 mm dies finishing options include nickel plating, non-stick coating or the super hard, long life HDT coating process.

The company also sees an important role for solid rotary dies to play in the production of labels and tags. Abrasive coated thermal papers and certain synthetic materials are best converted with a solid die that has either been chrome plated or hardened.

Recent investment in equipment and tooling means that Holfeld can now offer a fully hardened, machine finished die made from a special grade of tool steel. Initially supplied to converters of medical products these tools have been reported lasting 3 times longer than standard hardened dies. Label and tag producers can also take advantage of the benefits these dies can offer in terms of increased die life, reduced downtime and longer intervals between re-sharpening.

A versatile option comes from the company’s removable blade dies, which offers the option to sheet, perforate and kiss cut on the one tool. Interchangeable blades and the ability to use various slots within the overall die make these an attractive and flexible converting solution.

Material evolution

New thinner material formulations are targeting the reduction of resource consumption, liner weight and waste. Face materials, liners and adhesives are getting thinner and lighter. While this is necessary for the environment, it is a challenge for many parties in the value chain, including the press manufacturer, die maker, converter, and label applicator as it requires more sensitive web handling.

Ulrich Kretzschmar, product and business development manager flexible dies at RotoMetrics, explained the issues these thinner materials give converters, ‘Cutting dies have to deliver an extremely uniform liner strike to avoid excessive liner penetration and subsequently the risk of the liner breaking. The real challenge, though, is with the label converters. They not only have to get the right components but achieve perfect balance and process control. It’s more than just the die. It’s a flawless magnetic cylinder and an anvil with smooth surface and concentricity – all at the correct size. Undersized rolls can flex or bend resulting in uneven liner strike or lifting labels. It is recommended to inspect and audit all components on a regular basis.’

A well maintained die station with cutting pressure monitoring and lubrication system is critical as is a heat management system throughout the press to guarantee consistent cutting results across the entire run length.

Mr Kretzschmar continued, ‘Results can vary with every degree of temperature change. A real game changer is the AccuStrike adjustable clearance anvil. AccuStrike Anvils allow operators to adjust bearers independently or in unison for unparalleled control over die strike and changes in liner thickness. If you want to stay ahead of the game, investing in an AccuStrike pays back in no time.’

ETI Converting has also made steps to improve die-cutting on thinner substrates. The Canadian company, based in Quebec, has recently received a patent for its apparatus and method for cutting facestock.

The company wanted to put the patent in place prior to drupa to reinforce its concept of die-cutting extremely thin release liners (12 to 18 microns).

Named the Pellicut, the high speed rotary die-cut unit aims to avoid the die-cutting mark problems on paper and film liners completely, reduce costs of material by halving the amount of liner waste, which will lead to less rewinding time since there are more labels per roll.

According to the company, this technology guarantees that the die will not mark the liner during the die-cutting process and that there will be no breaks on labelling machines.

This equipment can die-cut pressure-sensitive material at a speed of 150 m/min and uses a standard flexible magnetic die. The W anti-deflection system avoids pressure cutting variations and reduces risks of die-cutting marks on the liner. An equaliser system corrects the thickness inconsistency of the magnetic plate presently sold on the market. Moreover, the cutting pressure is not sensitive to heat variations in the long run and during a continuous usage.

Adaptability

As materials change and grow in number, it is important for a printer to be able to adapt to whatever demand their customer has for them. Spilker’s newest product Mechanical Ejector Pins (MEP) can help printers become more flexible in the types of materials they can process.

Mechanical ejector pins press the material out of the tool. The cutting outlines do not get choked and the cutting lines are protected. Each individual pin is ground to the exact height and provided with a chamfer so that the material is not damaged.

The MEP from Spilker is capable of achieving small punches down to 1 mm in diameter

The tool is capable of achieving small punches down to as little as 1 mm in diameter. It is suitable for a wide range of applications including labels and can work with particularly thick materials due to its spring deflection of the ejector pins, which can be adjusted, to the material to be cut.

At drupa, Berhalter will be presenting a new die-cutting tool concept for in-mould labels (IML) that offers the advantages of favourable tool cost in combination with short lead times.

The LABEL-light punching tool is a patented concept combining the improvements of the flatbed die-cutting such as print-to-die registration and perfect handling properties. The costs for this punching tool is up to 70% lower compared to a traditional punching tool even allowing a label contour correction of +/- 0.5 mm. It has been designed especially for a cost efficient production of small to medium size IML label volumes.

Lasers

Laser cutters are becoming more and more popular within the labels market according to Mike Bacon, vice president of sales and marketing for Spartanics.

‘Laser die-cutting is a technology that many label printers are no longer simply investigating, they are investing in the technology. Our partnership with SMAG Graphique gives our customers the ability to integrate laser technology initially or integrate laser die cutting at some point in the future, and this is a real benefit for small to mid-level label producers.’

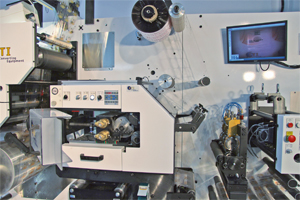

The Pellicut mini from ETI Converting has recently received a US patent

As the North American distributor for SMAG, the company continues to integrate laser cutting technology with SMAG’s technology developments. Its traditional offline finishing equipment, including the E-Cut and Digital Galaxie finishing systems, are now fully integrated with the X350 Laser Cutting Module from Spartanics. By introducing 200 and 400 Watt laser die-cutting technology to the line of traditional rotary die-cutting and screen printing equipment, the two companies can offer a system with a laser cutting module or integrate the X350 at some point in the future.

Focusing on the label market in particular, Spartanics is also a partner to INX International which has seen the company’s laser cutting technology incorporated into the NW210 UV Inkjet Printer, which also includes lamination, corona treatment, rotary sheeting for variable sheet lengths and bursting modules for quick separation of laser-perforated jobs.